| For other decisions covering production finish, walkways, aerial installations, camera gun, etc., reference must be made to the minutes of the meeting.

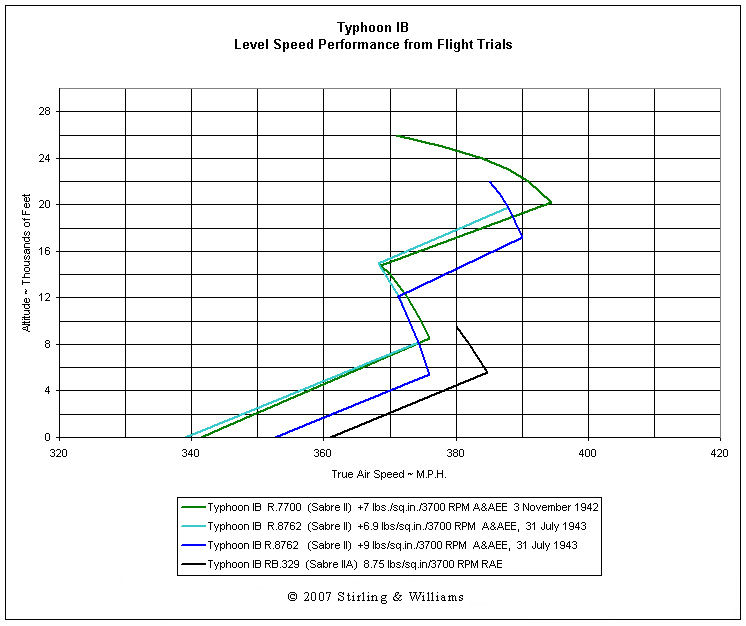

Production Level Speeds.

Tests of level speeds at Langley have given the following corrected figures:-

| R.7678 | 381 m.p.h. at 20,000 ft. (4 cannon)

| | R.7632 | 381 m.p.h. at 19,000 ft.

| | R.7577 | 383 m.p.h. at 19,200 ft.

|

| The above are all Gloster production aircraft. No level speeds were done on a Langley production aircraft for comparison.

July 1942.

Cleaning up of Typhoon 1.

Level speeds of production aircraft:- Full tests have been done at Gloster on the level speeds of 4 recent production aircraft of average finish. The maximum level speeds obtained were:

|

| Typhoon 1A. R.7914 | 397.5 m.p.h. at 20,500 ft. F.S.

| | 385 m.p.h. at 8,400 ft. M.S.

| | Typhoon 1A. R. 7869 | 396.5 m.p.h. at 20,100 ft. F.S.

| | 379 m.p.h. at 8,000 ft. M.S.

| | Typhoon 1B. R. 8650 | 393 m.p.h. at 20,800 ft. F.S.

| | 382 m.p.h. at 8,800 ft. M.S.

| | Typhoon 1B. R. 8636 | 392 m.p.h. at 20,000 ft. F.S.

| | 379 m.p.h. at 8,200 ft. M.S.

|

| These speeds are better than anything yet obtained at Langley on a production machine, and every effort should be made to maintain and improve this standard.

Drawings for the internal mass balanced rudder have been issued for production. Drawings for the cannon fairings have also been issued.

Mr. Camm has sent instructions that walkways are to be left off present production machines. Alternative materials are being tried, although it is not easy to reach service requirements.

The whip aerial modification has been incorporated with the modification deleting the crash pylon.

August 1942.

Cleaning up Typhoon 1.

Level speeds of production aircraft.

Level speeds done at Gloster Aircraft on a Typhoon 1B (R.8705) with short exhaust pipes, gave the following maximum level speeds.

|

| F.S. (M.P.A.) | 403.5 m.p.h. at 20,650 ft.

| | M.S. (M.P.A.) | 392.5 m.p.h. at 8,750 ft.

|

| Progress of modifications.

|

| (1) | The internally massed balance rudder and the cannon fairings are going into production.

| |

| | (2) | A new fairing on the outboard Chatellerault feed has been fitted for a trial installation.

| |

| | (3) | Tail wheel doors:- drawings are being prepared which will be suitable for Typhoon 1 and for the larger tail wheel on the Tempest.

| |

| | (4) | The introduction of the whip aerial installation is dependant upon present modifications to the cabin top.

|

| September 1942.

Cleaning up R.8222. F.R.710.

As a result of the recommendation made by the meeting held at the M.A.P. on the 4th of September, it has been decided that in order to obtain the maximum possible speed, all Service Typhoons will in future be fitted with short exhaust pipes, and in order to counteract C.O. contamination, oxygen for 30,000ft will be used during flight. This is regarded as an interim measure pending the completion of ventilation and louvre tests.

The excellent speeds obtained on a Gloster 1B production aircraft mentioned in the monthly summary for August have been confirmed by tests on the first Langley production 1B. This improvement in performance is due not only to the short exhausts but also the general improvement of finish, fits and paintwork on production aircraft, and to improved carburetion.

Level speeds obtained on R.8222 with 4” extended exhaust pipes were as follows.

|

| F.S. M.P.A. | 393 m.p.h. at 19,700ft.

| | M.S. M.P.A. | 382 m.p.h. at 8,400ft.

|

| Position of cleaning up modifications.

| |

| | (1) | Walkways:- A satisfactory painted on walkway has been developed at Langley and tested in service. This is now applied to all production Typhoons.

| |

| | (2) | Internal mass balance rudder:- It is understood from Mr. (illegible) at Gloster that this will be introduced on production aircraft by mid October and retrospective action will be underway in November.

| |

| | (3) | Cannon fairings:- These are being introduced in production.

| |

| | (4) | 4 Blade propeller:- It is understood that the 4 blade propellers will be available from January 1943 onwards.

| |

| | (5) | Whip aerial:- This has been found to function satisfactorily on the Tempest prototype. Its introduction on the Typhoon 1 is bound up with the modification for the deletion of the crash pylon.

| |

| | (6) | Fairing for outboard Chatelleraut feed:- These are being fitted to an aircraft for a T.I. at Langley.

| |

| | (7) | Tail wheel doors:- Work is proceeding.

| |

| | (8) | Shrouded exhaust system:- Messrs. Napier have developed a shrouded exhaust system for the short exhaust pipes which gives very satisfactory flame damping and glow suppression and an increase in speed of about 6 m.p.h. according to Napier tests.

| |

| | This installation is to be tested at Langley.

|

| As a result of the above modifications a further improvement in Typhoon 1 performance can be expected as from (illegible) October.

Aircraft Typhoon 1B R.8222. Engine Sabre II S 421. Airscrew DH Hydr 56113. Weight 10,630lbs.

Rate of roll with standard wing tips R.7577 (F.R. L.670)

The following are the times taken in rolling from 45 deg port to 45 deg starboard, and starboard to port, in accordance with the sighting line, marked on the armoured screen of the aircraft.

|

| Starboard to port | Port to starboard.

| At 200 A.S.I | 2.03 secs average | 1.86 secs average

| | At 300 A.S.I | 1.95 secs average | 1.87 secs average

| |

| Aircraft. Typhoon 1A R.7577. Engine Sabre II S 211. Airscrew DH Hdr.52046. Weight 10,600lbs.

December 1942.

Production level speeds. D.N 340 (F.R. L.776)

The above aircraft arrived at Langley for modification. As it was found to incorporate recent cleaning up modifications, (i.e. cannon fairings, internal mass balance rudder and painted on walkways), it was decided to check the level speed performance. The following results were obtained with short exhaust pipes fitted. (Corrected by method A. & A.E.E. Res.170).

|

| Max. Level speed M.S. M.P.A. 386 m.p.h. at 8,900'

| | Max. Level speed F.S. M.P.A. 400 m.p.h. at 20.800'

|

| A plot of the level speed points obtained showed that they were comparable with those of prototype P.5216 when fitted with 4 cannons. The M.P.A. speeds obtained on P.5216 corrected on the same basis were:-

|

| Max. Level speed M.S. M.P.A. 388 m.p.h. at 8,100'

| | Max. Level speed F.S. M.P.A. 405 m.p.h. at 20,800'

|

| The results on D.N.340 which was an aircraft picked at random, are particularly encouraging as the engine installed was known to be some 45 h.p. down in power in the M.S. gear.

Further improvements in the performance will occur with the fitting of the Napier exhaust shrouds and of the 4-blade propeller.

Aircraft. Typhoon 1B D.N 340. Engine. Sabre II S 599. Airscrew. DH Hydr. Weight 9,800lbs.

January 1943.

Handling with Sliding Hood. R.8809 (F.R. 797, 794, 801, 802)

Pilots, who have flown with the sliding hood, find that the absence of door pillars and framework tends to give a greater sense of confidence and mastery over the aircraft. Another important feature from the point of view of pilot’s comfort is that there is noticeably less noise than with the standard cabin top.

The aircraft has been dived to 500 A.S.I. at 10,000ft with the hood closed.

With the hood open, it has been flown up to 250 A.S.I. and no signs of turbulence have appeared.

After the initial tests, when the hood could not be opened at more than 120 A.S.I. the gearing of the mechanism was altered, and it is now just possible to open the hood at 180 A.S.I. Further attempts to reduce friction in the mechanism are being made.

Complete icing up of the quarter panels was reported on an early flight, and tests are proceeding to remedy this.

Level speed figures obtained have indicated that there is an increase in performance compared with he standard version. Full throttle figures (corrected using A. & A. E. E. Res 170) were as follows.

|

| M.S. M.P.A. 396 m.p.h. (true) at 8,300ft.

| | F.S. M.P.A. 406 m.p.h. (true) at 19,900ft.

|

| This performance is the best yet obtained on a production Typhoon. As this machine has an external mass balanced rudder, “wondergrip” walkways and no cannon fairings, a further improvement in performance can be expected when cleaning up modifications are incorporated.

Aircraft. Typhoon 1B R.8809. Engine. Sabre II S 58. Airscrew. DH Hydr. Weight. 9,700lbs.

February 1943.

Sliding hood. R.8809, (F.R. L.822,832)

Further tests have been carried out to test the opening and shutting of this hood in the air. To assist opening, two lengths of elastic have been attached to the forward end of the hood, giving a total backward pull of 40lbs. when the hood is closed. Although it is rather difficult to close the hood while on the ground, it can now easily be opened in the air at 200 m.p.h. A.S.I. It is also just possible to open the hood at 250 A.S.I.

Shutting the hood in the air is easy. Some method must be found of closing the hood from the outside when the machine is on the ground, as at present it is possible that the hood will get scratched and dirty if closing is attempted by the present method of just pushing on the cabin top.

Level speed checks gave the following results:-

|

| Gear. | Standard Height. | True Air Speed. |

| |

| | M.S. | 8,800 | 392

| | F.S. | 20,700 | 409

|

| Aircraft. Typhoon 1B 8809. Engine Sabre II S 58. Airscrew DH Hydr. Weight 9,700lbs.

April 1943.

Production level speeds.

Level speed figures have been obtained from Gloster Aircraft Co. on two recent production Typhoons. These aircraft had short exhaust pipes, internally mass balanced rudders and cannon fairings.

Levels obtained for the two aircraft at M.S. m.p.h. were as follows (corrected to A. & A. E. E. Res.170)

|

| Typhoon 1B. KK.288 | 388.5 m.p.h. (true) at 8,360ft.

| | Typhoon 1B. KK.271 | 389.5 m.p.h. (true) at 8,430ft.

|

| May 1943.

Cleaning up: Comparative Tests of exhaust shrouds

EK. 229 (F.R.L. 907, 908, 909, 913 and 914)

Comparative level speeds were done to compare the bulged exhaust shrouds and flanged pipes with the original shrouds and exhaust pipes. There was no noticeable difference in speed between the two installations. Speeds obtained for both sets of pipes corrected by different methods were as follows:

|

| |  | A. & A.E.E. Res.170 |

| |

| | M.P.A | M.S. | 394 m.p.h. | 394 m.p.h.

| | M.P.A. | F.S. | 410 m.p.h. | 414 m.p.h.

|

| This is as fast as the prototype P5212 without cannon fitted.

Aircraft. Typhoon 1B EK.229. Engine. Sabre II S 722. Airscrew. DH Hydr 56074. Weight 9,700lbs.

August 1943.

Cleaning up.

The remaining cleaning up modifications are now on the production machine.

|

| These are | (a) Exhaust shrouds.

| | (b) Whip aerial

| | (c) Sliding hood.

|

| Tests at Gloster on a repaired aircraft with a whip aerial and sliding hood fitted have given the following level speeds corrected on the basis of A. & A.E.E. Res.170.

|

| M.S. M.P.A | 398 m.p.h. at 8,800ft

| | F.S. M.P.A | 417 m.p.h. at 20,500ft.

|

| This represents an increase of some 7 m.p.h. in F.S. and some 4 m.p.h. in M.S. due to the sliding hood and aerial.

They are the fastest speeds yet obtained on any Typhoon aircraft. The maximum speed is some 12 m.p.h. better than the prototype Typhoon 1B and represents a total increase of some 35 m.p.h. compared with the worst Typhoons tested at Langley.

December 1943.

Level speeds of production aircraft. J.R.333 (F.R.L.1104, 1108).

J.R.333, one of the first aircraft off the Gloster production line to be fitted with a sliding hood, was tested for level speed at Langley. The results, however, were disappointing when compared with the performance of R.8805 with a sliding hood.

The maximum speed attained corrected by the method of A. & A.E.E. Res.170 was:

|

| F.S. M.P.A. | 413 m.p.h. at 19,500ft.

|

| M.S. M.P.A. appeared to be about 390 m.p.h. although no levels were done below 9,000ft. This aircraft was fitted with interim production exhaust shrouds.

Aircraft. Typhoon 1B J.R.333. Engine. Sabre II A S1914. Airscrew. DH Hydr. Weight. 11,295lbs.

Typhoon Production

Typhoon Production

- All Typhoon production was centered on Gloster Aircraft Company Ltd., Brockworth, Gloscester. However, a single production batch of 15 aircraft was produced by Hawker at Langley, being intended as trials aircraft, some were however delivered to the RAF.

R8198 to R8231. R8198 first flight 26-11-41. Mk1a and Mk1b.

- First batch of 250 Mk 1a and 1b. R7576-R7599, R7613-R7655, R7672-R7721, R7738-R7775, R7792-7829, R7845-R7890 and R7913-R7923. Delivered between September 1941 and June 1942.

- Second batch of 250 Mk 1a and 1b. R8630-R8663, R8680-R8722, R8737-R8781, R8799-R8845, R8861-R8900, R8923-8947 and R8966-R8981. Delivered between June 1942 and September 1942.

- Third batch of 700 Mk1b. 300 aircraft DN241-DN278, DN293-DN341, DN356-DN389, DN404-DN453, DN467-DN513, DN529-DN562 and DN576-DN623. 400 aircraft EJ900-EJ934, EJ946-EJ995, EK112-EK154, EK167-EK197, EK208-EK252, EK266-EK301, EK321-EK348, EK364-EK413, EK425-EK456, EK472-EK512 and EK535-EK543. Delivered between September 20th 1942 and May 5th 1943.

- Fourth batch of 600 Mk1b. JP361-JP408, JP425-JP447, JP480-JP516, JP532-JP552, JP576-JP614, JP648-JP689, JP723-JP756, JP784-JP802, JP836-JP861, JP897-JP941, JP961-JP976, JR125-JR152, JR183-JR223, JR237-JR266, JR289-JR338, JR360-JR392, JR426-JR449 and JR492-JR535. Napier Sabre IIa from new, many aircraft modified with Sabre IIb engines in 1944. Later aircraft featured sliding hood from new, majority of earlier aircraft retrospectively modified. Delivered between April 5th 1943 and December 7th 1943.

- Fifth batch of 800 aircraft. MM951-MM995, MN113-MN156, MN169-MN213, MN229-MN269, MN282-MN325, MN339-MN381, MN396-MN436, MN449-MN496, MN513-MN556, MN569-MN608, MN623-MN667, MN680-MN720, MN735-MN779, MN791-MN823, MN851-MN896, MN920-MN956, MN968-MN999, MP113-MP158 and MP172-MP203. All aircraft with sliding hood, whip aerial, faired cannon and Sabre II, most with four blade propeller. Delivered between December 8th 1943 and June 6th 1944.

- Sixth batch of 400 aircraft. PD446-PD480, PD492-PD536, PD548-PD577, PD589-PD623, RB192-RB235, RB248-RB289, RB303-RB347, RB361-RB408, RB423-RB459 and RB474-RB512. All aircraft with sliding hood, whip aerial, faired cannon, exhaust shrouds and four blade propeller, most aircraft with Napier Sabre IIa engine but a few among the final 255 were powered by the Napier Sabre IIb. Delivered between June 15th 1944 and January 5th 1945.

- Seventh and final batch of 300 aircraft 299built. SW386-SW428, SW443-SW478, SW493-SW537, SW551-SW596, SW620-SW668, SW681-SW716 and SW728-SW772. Napier Sabre IIb engines. Delivered between January 5th 1945 and November 13th 1945.

|

[WWII Aircraft Performance]

[AFDU Tactical Trials - Typhoon I Aircraft ]

[Tempest Performance]

|